Automation in Logistics: Driving Efficiency in Saudi Arabia’s Warehousing Sector

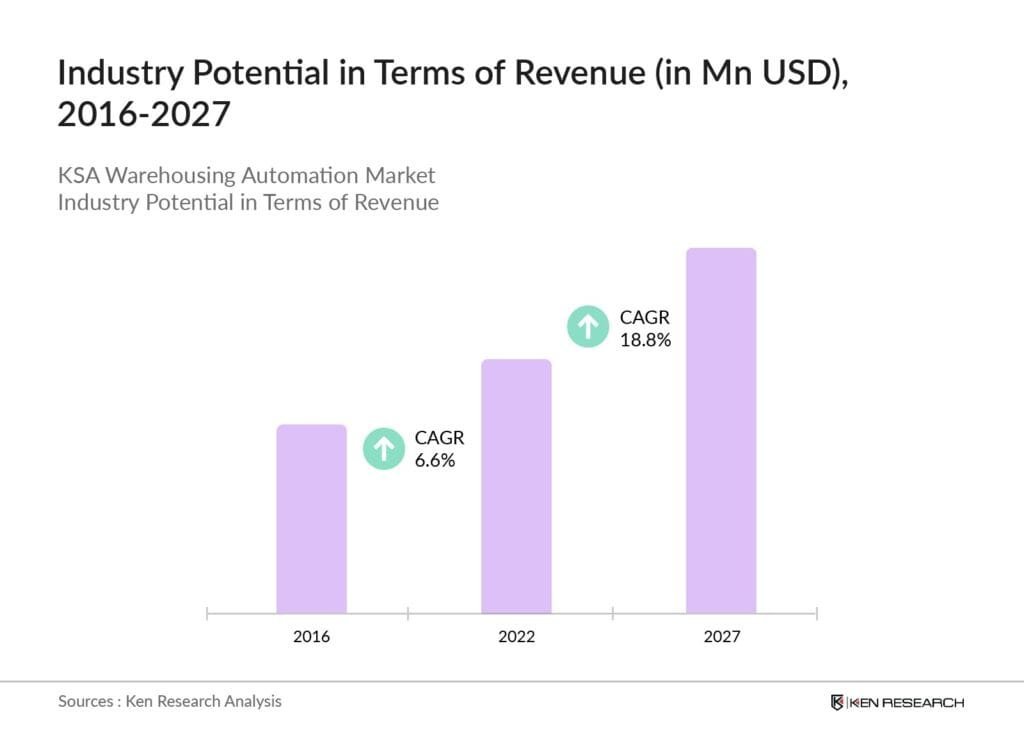

As Saudi Arabia continues to diversify its economy through its ambitious Vision 2030 initiative, the logistics and warehousing sector is experiencing a transformative phase. With a strategic location at the crossroads of Asia, Europe, and Africa, Saudi Arabia is positioning itself as a global logistics hub. Central to this evolution is automation in logistics, which is rapidly reshaping warehousing, sorting, and shipping processes across the country. According to research, the KSA warehousing automation market showed a steady CAGR of 6.6% between 2016 and 2022. However, growth is expected to accelerate, with forecasts projecting a CAGR of 18.8% by 2027. This remarkable expansion highlights the critical role automation will play in positioning Saudi Arabia as a regional logistics leader.

This article explores how automation in logistics is driving efficiency in Saudi Arabia’s logistics sector and highlights key data points that demonstrate the impact of technological advancements on the market.

The Growing Importance of Automation in Saudi Logistics

The demand for efficient and technologically advanced logistics solutions has grown significantly in Saudi Arabia, driven by the expansion of e-commerce, retail, and industrial sectors. Saudi Arabia is investing $35 billion into logistics infrastructure, creating new opportunities for automation in warehousing and shipping. This transformation is key to achieving the goals of Vision 2030, particularly as Saudi Arabia seeks to reduce its reliance on oil and position itself as a global trade hub.

The Saudi warehousing market has seen substantial growth, with cities like Jeddah, Riyadh, and Dammam playing pivotal roles in this expansion. Jeddah, with its strategic location on the Red Sea, is home to over 26.1 million square meters of warehousing facilities, making it a major logistics hub. Riyadh, the capital city, boasts 24.5 million square meters of logistics parks, while Dammam has 20.9 million square meters dedicated to warehousing.

With the Saudi logistics sector on the rise, automation is becoming an essential tool for maintaining efficiency and meeting the growing demand.

Key Automation Advancements in Saudi Warehousing

To support this rapid expansion, automation in logistics is now seen as a critical factor in improving operational efficiency and reducing costs. Some of the major automation advancements transforming Saudi Arabia’s logistics sector include:

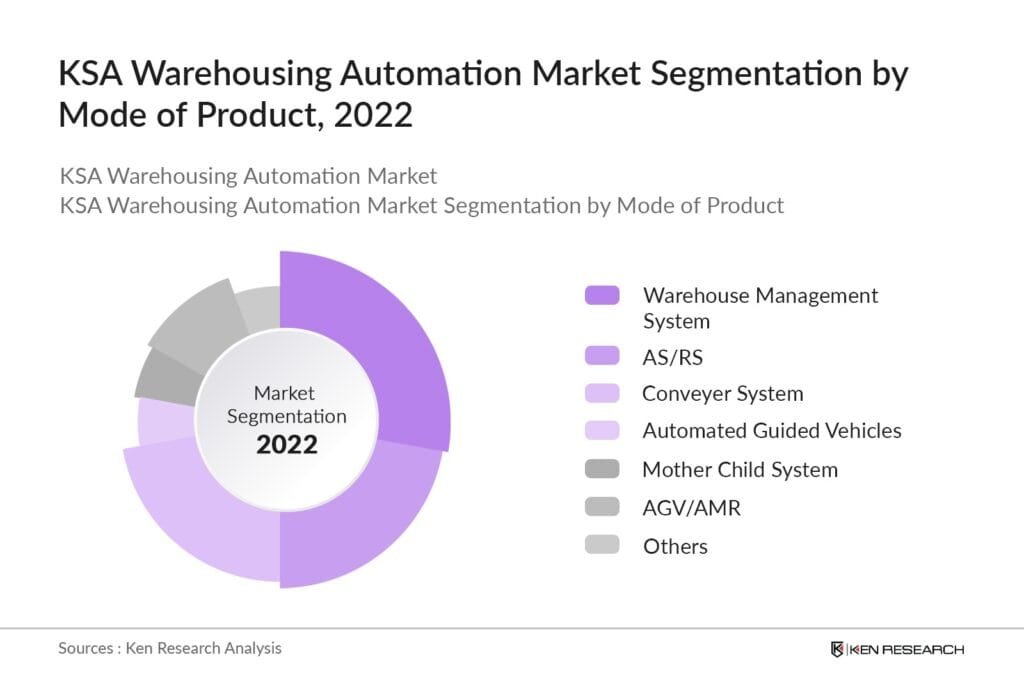

1. Warehouse Management Systems (WMS)

Accounting for a significant portion of the market, WMS software automates the tracking, managing, and optimizing of warehouse operations. WMS allows companies to streamline inventory control, reduce human errors, and increase throughput. Key logistics companies operating in Saudi Arabia utilize WMS to optimize their logistics operations across major cities like Riyadh, Jeddah, and Dammam.

2. Automated Cold Storage Solutions with AS/RS Integration

In response to rising demand from the pharmaceutical and food industries, particularly following the COVID-19 pandemic, Saudi Arabia has made significant investments in automated cold storage solutions. A key technology driving these innovations is Automated Storage and Retrieval Systems (AS/RS), which play a crucial role in optimizing space and maintaining precise temperature control in cold storage environments.

By utilizing AS/RS, cold storage facilities can efficiently store and retrieve temperature-sensitive goods such as vaccines and perishable foods, ensuring minimal exposure to external temperatures. This automation reduces labor dependency in challenging cold environments, enhances product traceability, and upholds strict quality and regulatory standards. As a result, AS/RS systems are helping Saudi Arabia maintain an efficient cold supply chain, while supporting the growing demand for high-quality storage and distribution of sensitive products.

The rise in cold storage demand is driven by industries such as food and pharmaceuticals, with companies adopting automation to maintain quality standards and meet regulatory requirements. These solutions are crucial for temperature-sensitive goods like vaccines and perishable food products.

3. Robotics and AI-Driven Sorting Systems

Automation in sorting and shipping is helping companies manage larger volumes of products with increased speed and accuracy. By leveraging robotics and artificial intelligence (AI) in their warehouses, logistics companies in Saudi Arabia can automate the sorting of goods, reducing human errors and expediting shipping processes.

Automated Guided Vehicles (AGVs), self-driving vehicles that follow predefined routes without human intervention, streamline the internal transport of goods within warehouses. AGVs eliminate manual handling and ensure goods are swiftly transported across different warehouse zones. Meanwhile, Autonomous Mobile Robots (AMRs) operate independently, navigating dynamic environments and adjusting to changing routes as they handle material transport tasks. Together, AGVs and AMRs boost warehouse efficiency, minimize delays, and enable logistics companies to meet growing demand with greater accuracy and reliability.

4. Internet of Things (IoT) Integration

Real-time tracking and monitoring of goods is made possible by IoT technology, which is improving warehouse operations. IoT devices can be embedded into shipments, enabling companies to monitor the location and condition of products throughout the supply chain. This level of visibility helps warehouses optimize processes, reduce delays, and improve overall efficiency.

With IoT devices in place, Saudi Arabia’s logistics companies can ensure the seamless flow of goods and maintain high levels of customer satisfaction.

The Future of Automation in Saudi Logistics

The future of Saudi Arabia’s logistics market lies in embracing automation technologies to meet the demands of an increasingly competitive global market. As the country continues to invest in logistics infrastructure, the integration of advanced automation tools will be key to positioning Saudi Arabia as a regional and global logistics powerhouse.

With the warehousing market in Saudi Arabia projected to grow steadily, the use of automation will become even more critical in helping companies manage the rising demand for efficient logistics solutions.

Conclusion

The rise of automation in logistics is reshaping Saudi Arabia’s logistics landscape, driving efficiency, and positioning the country as a major player in the global logistics market. By adopting advanced warehouse management systems, cold storage solutions, robotics, and IoT technology, Saudi Arabia is taking significant steps toward becoming a logistics hub capable of handling the demands of a growing e-commerce and retail market.

With continued investment in logistics infrastructure, Saudi Arabia is well on its way to achieving the goals outlined in Vision 2030 and becoming a leader in the global logistics market.